Scientists Find Way To Grow Skin In The Shape Of Human Hands That Can Be Pulled On ‘Like A Glove’

Have you ever attempted to wrap an oddly shaped gift, like a stuffed animal or something with an odd shape, it’s not fun. This is a little bit like what surgeons need to deal with when presented with patients that require artificial skin on certain injured body parts.

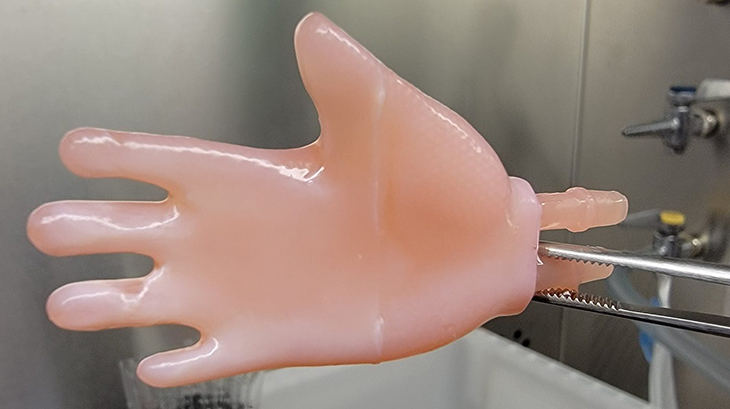

But in recent years, bioengineers have managed to create a new way of growing skin in the shape of a human hand in order to make it easier for surgeons to graft personalized skin onto burn victims in the future.

At the moment, engineered skin is created in flat pieces. And when compared to wrapping paper, it can be very hard and time-consuming when attempting to stich these pieces together around an irregularly shaped body part, like a hand or foot.

However, researchers from Columbia University are now saying that by engineering skin cells into complex, three dimensional shapes during mice experiments have found to be the revolutionary first step for the future.

According to lead developer and assistant professor of dermatology at the university’s Vagelos College of Physicians and Surgeons, Hasan Erbil Abaci, PhD said, “Three-dimensional skin constructs that can be transplanted as ‘biological clothing’ would have many advantages. They would dramatically minimize the need for suturing, reduce the length of surgeries, and improve aesthetic outcomes.”

Published in the January 23, 2023 copy of Sciences Advances, the study also showed that ‘the continuous 3D grafts have better mechanical and functional properties than conventional, pieced-together grafts.’

“We hypothesized that a 3D fully-enclosed shape would more closely mimic our natural skin and be stronger mechanically, and that’s what we found. (It) significantly improves the composition, structure, and strength of the graft,” Abaci added.

He also said, “Another compelling use would be face transplants, where our wearable skin would be integrated with underlying tissues like cartilage, muscle, and bone, offering patients a personalized alternative.”

The research group explained that the process of creating new skin grafts start with a 3D laser scan of the target structure, whether the human hand, the foot, the ear, or whatever part it needs. Afterwards, a hollow and permeable model of the hand – for example – is made using computer-aided design and 3D printing.

Meanwhile, the exterior of the model is then ‘seeded with skin fibroblasts, which generate the skin’s connective tissue, and collagen (a structural protein.’ To cap it off, the outside of the mold is then coated with a mixture of keratinocytes, cells that make up most of the outer layer of skin – also called epidermis – while the inside is perfused with growth media in order to support and nourish the developing skin graft.

Unlike with usual 3D printing, when it comes to skin grafts, rather than using the 3D scaffold, the researchers use the same procedures as they do to make flat engineered skin. Moreover, the whole process also took around the same about time, which was about three weeks in total.

During the first test of the 3D engineered skin, doctors managed to successfully graft on constructs of composed human skin cells to the hand limbs of mice.

Abaci went on to say, “It was like putting a pair of shorts on the mice. The entire surgery took about 10 minutes.”

By four weeks, the grafts had already integrated completely with the surrounding mouse skin, while the mice also reacquired the functions of the limb completely as well. Because mouse skin feels differently from human skin, human clinical trials are needed but probably many years away still.

According to the researchers, their 3D grafts are indeed the pioneering major re-design of engineered skin grafts since their very first time they made their debut back in the early 80s.

A report in EurekAlert! shared that Abaci said, “Engineered skin started with only two cell types, but human skin has around 50 types of cells. Most research had focused on mimicking the cellular components of human skin. As a bioengineer, it’s always bothered me that the skin’s geometry was overlooked and grafts have been made with open boundaries, or edges. We know from bioengineering other organs that geometry is an important factor that affects function.”

Because of this groundbreaking research, Abaci and his team share that they believe they can make more lifelike grafts when 3D printers become more available, alongside the ability to create the three-dimensional scaffolds or plans needed to make these special types of engineered skin.

Abaci also sees that in the future, skin grafts could eventually become custom-made for a particular patient’s own skin cells. Using just a 4×4 millimeter sized sample of skin, scientists could have enough cells to culture and multiply, enough to create skin that could cover an entire human hand.